BLOG

First battle victorious: Three Guarantees, Five Comparisons, 100-Day Intensive Effort—The first batch of modular skids for the Anyue Second Purification Plant and its outbound transportation system construction project in the Southwest Oil & Gas Field has been successfully shipped.

2025-04-28

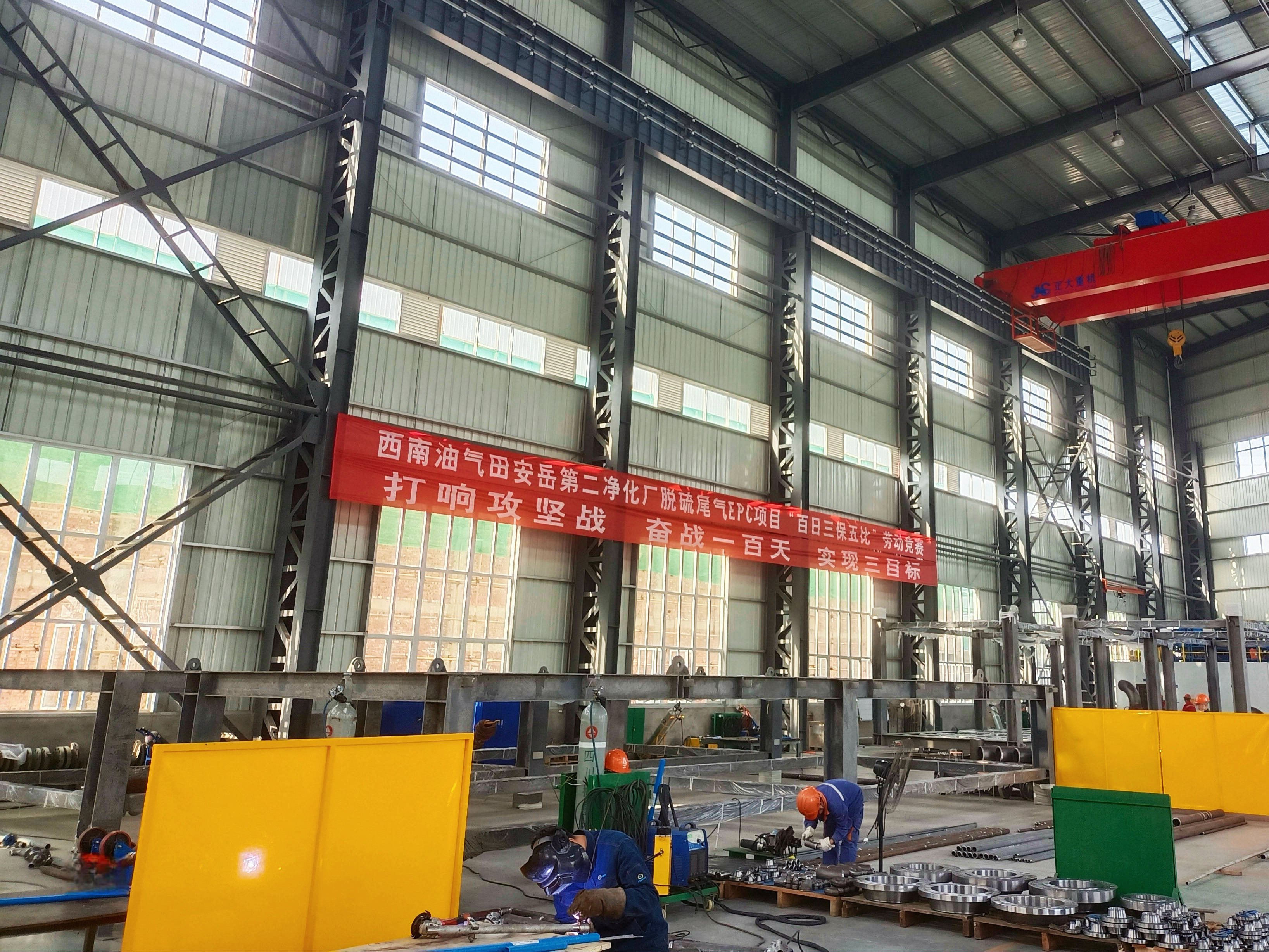

On April 24, 2025, the first batch of modular skids for the construction project of the Anyue Second Purification Plant and its outbound transportation system—undertaken by our company—was successfully shipped. Located in Anyue County, Ziyang City, Sichuan Province, the project boasts an annual processing capacity of 4 billion cubic meters and is a key initiative under PetroChina's "14th Five-Year Plan," as well as a critical component of the Southwest Oil & Gas Field Company's "Double Ten Project." Our company is primarily responsible for Package A of the desulfurization module for this project, which includes the production of 16 skids comprising demister modules, desulfurization modules, and filtration-separation modules.

After securing the project, our company immediately assembled a dedicated project management team and a skilled technical team. The project team meticulously planned the strategy, implemented scientific project management practices, and actively responded to the client’s call by launching the "Three Guarantees, Five Comparisons" 100-Day Intensive Effort Campaign. Faced with tight deadlines and overwhelming tasks, all departments within the company clearly defined their roles and worked closely together, maintaining rigorous oversight of every stage and process. The project team continuously monitored progress, ensuring real-time awareness of project developments. Meanwhile, the procurement team assigned multiple members to remain on-site at the factory, expediting the delivery of critical materials to guarantee timely arrival. In the production workshop, strict control was exercised over both schedule and quality—employees were required to pass competency tests before taking up their posts, while quality standards were upheld with unwavering precision. At the same time, staff worked overtime to keep pace with the demanding production timeline. The quality assurance team adopted a grid-based management approach, conducting thorough, round-the-clock inspections with no blind spots. Meanwhile, the technical team set up shop onsite, swiftly addressing issues as they arose. After 100 days of relentless effort, on April 24, 2025, we achieved a major milestone: the first batch of demisters—essential equipment for this project—was successfully shipped to the site. Simultaneously, other skids are now steadily progressing through the manufacturing process.

The smooth shipment of the first batch of mold blocks ensured that the client’s on-site installation could commence as scheduled, reflecting our company’s proactive and meticulous work ethic—and earning high praise from the client.

Going forward, our company will continue to deepen our collaboration with Southwest Oil & Gas Field Company, remaining fully committed to the project with enthusiasm and a professional approach throughout production and delivery. To ensure the project stays on track in terms of both schedule and quality, we will further optimize our production processes, enhance efficiency, and strengthen communication and coordination with the project team. This will guarantee seamless integration across every stage, enabling the smooth progress and high-quality completion of the An Yue Second Purification Plant and External Transportation System Construction Project at the Southwest Oil & Gas Field.